Senken New Launched Electric-Telescopic Mast:SGD SERIES

Nighttime operations, particularly fire rescue and emergency response missions, demand extremely high lighting standards: brightness must be sufficient, coverage must be extensive, and height must be flexibly adjustable to ensure uninterrupted operations.

This is not only a test of the lighting fixtures’ performance, but also a stringent test of the lifting masts’ quality, where the precision, stability, and reliability of height adjustment directly determine the lighting effectiveness.

Traditional lifting masts are mostly pneumatic, primarily relying on compressed air to generate pneumatic pressure as a power source for upward thrust. During descent, pressure is reduced through an exhaust valve, working in conjunction with gravity to complete the operation.

This pneumatic type is prone to the following problems:

Excessive equipment, poor portability: The lifting and lowering of pneumatic masts requires an air compressor, which itself is powered by electricity or an engine. The proliferation of equipment significantly reduces portability.

Poor environmental adaptability and weak anti-aging properties: Pneumatic lifting masts consist of multiple circular cylinders nested within each other, with rubber seals between each cylinder. Rubber material exhibits poor anti-aging performance and environmental adaptability, requiring specific temperature conditions. After a certain period, it automatically ages and loses its sealing properties, causing the mast to develop air leaks and other malfunctions that impair normal operation.

Unstable height adjustment and low precision: Due to factors such as the internal surface-finish of the pneumatic mast’s cylinders, unequal friction between cylinder walls and seals, and unstable pressure from compressed air, the lifting process produces shaking, impact, jumping, and other phenomena. Significant load settlement and suboptimal stability prevent it from meeting high-precision positioning requirements.

To address these issues and ensure stable, high-brightness performance of nighttime operation lighting, Senken has leveraged existing new technologies to specifically research, develop, and design the SGD electric/manual dual-function multi-purpose lifting mast.

SGD Electric or Manual Dual-Function Multi-Purpose Lifting Mast

Both Electric and Manual Modes Enable Stable Lifting and Lowering.

Square Cross-Section: Stable Operation in Level-8 Winds, Intact in Level-12 Winds.

Electric Drive, Simple and Efficient

The SGD electric/manual lifting mast is powered by a motor, requiring only a power supply to operate. Even in situations without power, lifting and lowering can be performed through manual mode, greatly improving mobility and flexibility.

Square Cross-section, 12-Level Wind Resistance

The cylinder body uses square cross-section profiles. Compared with traditional circular cross-section lifting masts, the square cross-section offers greater strength, rigidity, torsional resistance, and bending resistance, significantly improving overall wind resistance. It can operate normally in 8-level winds without guy ropes around the clock, and the mast remains intact in 12-level winds.

Smooth Lifting, High-Precision Positioning

The SGD electric/manual lifting mast uses high-efficiency trapezoidal screw transmission for power, providing a smooth lifting process without shaking, impact, or other phenomena. It also provides self-locking function at any position, with high positioning accuracy, maintaining relative height for extended periods without sinking.

Upgraded Structure, Extended Service Life

Lifting and lowering are both constructed on mechanical principles, without the rubber seals found in traditional pneumatic mast. No need to worry about defects such as aging and leakage of seals, resulting in a longer service life.

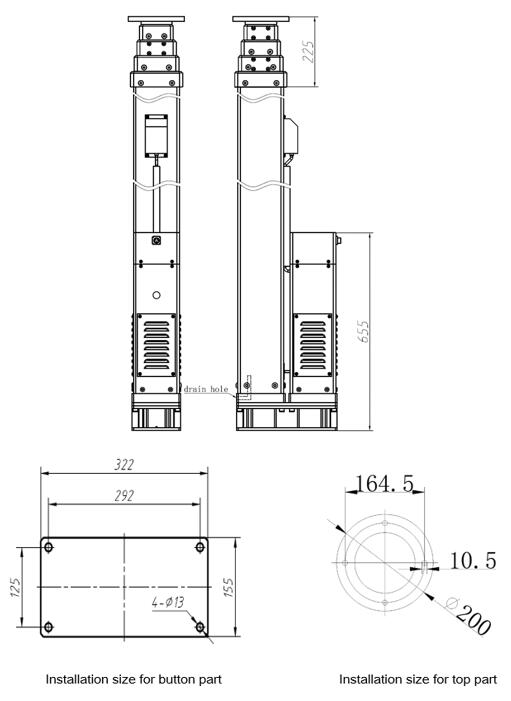

Personalized Customization, Demand Fulfillment

To meet various environmental usage requirements and adapt to different vehicle models, the lifting mast’s operating power supply, control method, top mounting dimensions, bottom mounting dimensions, closed height, and extended height can all be customized according to actual needs. Among these, height customization requires adjustment of the number of mast sections, with the current maximum extended height reaching up to 15 meters!

To Sum up, electric mast has advantage as below:

- Electric/Manual Operation Available

- Square Cross-section, Upgraded Structure

- Precise Positioning, Stable Operation

- Longer Service Life

- Also Customizable

If you are interested in our electric mast, please contact us for more information, thanks!